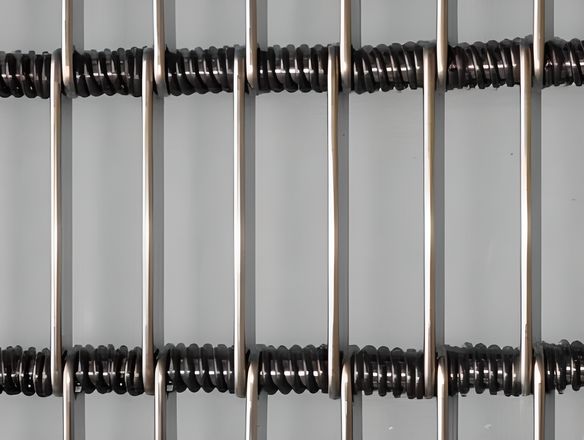

EFCB-01 Round Wire Eye Link Conveyor Belt.

Eye link Conveyor Belt, also called eye link conveyor belt, is specially designed for conveying large and heavy products. It has a large open area and a robust structure, ensuring the long lifespan of the Eye link conveyor belt.

The materials of the Eye link conveyor belt are typically stainless steel, carbon steel, and galvanized steel. They all feature excellent corrosion and rust resistance, as well as high-temperature resistance, making them suitable for high-temperature applications.

The Eye link conveyor belt consists of multiple strips. The strips are formed into eye shapes, and the different eye wires are connected by a cross rod to form the Eye link conveyor belt.

The eye-shaped strips can be round wires or flat sheets. The round wire eye link conveyor belt is the most common type, while the flat eye link conveyor belt can be customized to meet specific customer requirements.

EFCB-01 Round Wire Eye Link Conveyor Belt.

EFCB-02 Flat Sheet Eye Link Conveyor Belt.

In addition to the standard Eye link conveyor belt, there are three other types of Eye link conveyor belts for your selection. They have different characteristics, making them suitable for various applications and meeting different customer requirements.

EFCB-03 Standard Eye Link Conveyor Belt.

EFCB-04 Conveyor Belt with Under Welded Wire Spacing.

EFCB-05 Eye Link Conveyor Belt with Rings as Spacers.

EFCB-06 Eye Link Conveyor Belt with Springs as Spacers.

There are four types of conveyor belt edges, each with different features for various applications.

EFCB-07 Standard Edge Eye Link Conveyor Belt.

EFCB-08 Reinforced Edge Conveyor Belt.

EFCB-09 Chain Link Edge Eye Link Conveyor Belt.

EFCB-10 Side Guard Edge Eye Link Conveyor Belt.

| Types | Belt Pitch (Mm) |

Wire Diameter (Mm) |

Cross Rod Diameter (Mm) |

Minimum Gap (Mm) |

|---|---|---|---|---|

| BSCB-01 | 24.90 | 2.03 | 5.08 | 2.03 |

| BSCB-02 | 25.40 | 2.03 | 5.08 | 2.03 |

| BSCB-03 | 29.98 | 1.52 | 4.06 | 1.52 |

| BSCB-04 | 29.98 | 2.03 | 4.06 | 2.03 |

| BSCB-05 | 29.98 | 2.03 | 5.08 | 2.03 |

| BSCB-06 | 31.75 | 2.03 | 5.08 | 2.03 |

| BSCB-07 | 50.04 | 1.52 | 5.08 | 1.52 |

| BSCB-08 | 50.04 | 2.03 | 5.08 | 2.03 |

| BSCB-09 | 50.04 | 2.54 | 5.08 | 2.54 |

| BSCB-10 | 50.04 | 2.54 | 6.10 | 2.54 |

| BSCB-11 | 50.04 | 3.05 | 7.87 | 3.05 |

| BSCB-12 | 0,80 | 1.52 | 5.08 | 1.52 |

| BSCB-13 | 0,80 | 1.52 | 7.87 | 1.52 |

| BSCB-14 | 0,80 | 2.03 | 6.10 | 2.03 |

| BSCB-15 | 0,80 | 2.03 | 7.87 | 2.03 |

| BSCB-16 | 0,80 | 2.54 | 6.10 | 2.54 |

| BSCB-17 | 0,80 | 2.54 | 7.87 | 2.54 |

| BSCB-18 | 0,80 | 3.05 | 7.87 | 3.05 |

| BSCB-19 | 0,80 | 4.06 | 7.87 | 4.06 |

| BSCB-20 | 59,95 | 2.03 | 5.08 | 2.03 |

| BSCB-21 | 59,95 | 2.54 | 5.08 | 2.54 |

| BSCB-22 | 70,10 | 4.06 | 0,28" | 4.06 |

| BSCB-23 | 74.93 | 2.54 | 5.08 | 2.54 |

| BSCB-24 | 74.93 | 2.54 | 7.87 | 2.54 |

| BSCB-25 | 100.08 | 3.05 | 7.87 | 3.05 |

| Item | Belt Pitch (Mm) |

Wire Diameter (Mm) |

Cross Rod Diameter (Mm) |

Minimum Gap (Mm) |

Maximum Number of Welded Wires |

|---|---|---|---|---|---|

| BCBUW-01 | 15.875 | 1.8 | 3.2 | 2.00 | 1 |

| BCBUW-02 | 25.00 | 2.00 | 5.00 | 2.30 | 2 |

| BCBUW-03 | 25.40 | 2.00 | 5.00 | 2.30 | 2 |

| BCBUW-04 | 30.00 | 2.00 | 4.00 | 2.30 | 2 |

| BCBUW-05 | 30.00 | 2.00 | 5.00 | 2.30 | 2 |

| BCBUW-06 | 50.00 | 2.00 | 5.00 | 2.30 | 3 |

| BCBUW-07 | 50.00 | 2.50 | 5.00 | 2.80 | 3 |

| BCBUW-08 | 50.00 | 2.50 | 6.00 | 2.80 | 3 |

| BCBUW-09 | 50,80 | 2.50 | 8.00 | 2.80 | 3 |

| BCBUW-10 | 50,8 | 3.00 | 8.00 | 3.30 | 3 |

| BCBUW-11 | 75.00 | 2.50 | 5.00 | 2.80 | 3 |

| BCBUW-12 | 75.00 | 2.50 | 8.00 | 2.80 | 3 |

| Item | Belt Pitch (Mm) |

Wire Diameter (Mm) |

Cross Rod Diameter (Mm) |

Minimum Gap (Mm) |

|---|---|---|---|---|

| BCBRS-01 | 25.00 | 2.00 | 5.00 | 4.00 |

| BCBRS-02 | 25.40 | 2.00 | 5.00 | 4.00 |

| BCBRS-03 | 30.00 | 2.00 | 4.00 | 2.00 |

| BCBRS-04 | 30.00 | 2.00 | 5.00 | 4.00 |

| BCBRS-05 | 31.75 | 2.00 | 5.00 | 4.00 |

| BCBRS-06 | 50.00 | 2.00 | 5.00 | 4.00 |

| BCBRS-07 | 50.00 | 2.50 | 5.00 | 5.00 |

| BCBRS-08 | 50.00 | 2.50 | 6.00 | 5.00 |

| BCBRS-09 | 50,80 | 2.50 | 6.00 | 5.00 |

| BCBRS-10 | 50,80 | 2.50 | 8.00 | 5.00 |

| BCBRS-11 | 50,80 | 4.00 | 8.00 | 8.00 |

| BCBRS-12 | 60.00 | 2.00 | 5.00 | 4.00 |

| BCBRS-13 | 60.00 | 2.50 | 5.00 | 5.00 |

| BCBRS-14 | 75.00 | 2.50 | 5000 | 5.00 |

| BCBRS-15 | 75.00 | 2.50 | 8.00 | 5.00 |

| Item | Belt Pitch (Mm) |

Wire Diameter (Mm) |

Cross Rod Diameter (Mm) |

Minimum Gap (Mm) |

|---|---|---|---|---|

| BCBSS-01 | 25.00 | 2.00 | 5.00 | 4.00 |

| BCBSS-02 | 25.40 | 2.00 | 5.00 | 4.00 |

| BCBSS-03 | 30.00 | 2.00 | 4.00 | 2.00 |

| BCBSS-04 | 30.00 | 2.00 | 5.00 | 4.00 |

| BCBSS-05 | 31.75 | 2.00 | 5.00 | 4.00 |

| BCBSS-06 | 50.00 | 2.00 | 5.00 | 4.00 |

| BCBSS-07 | 50.00 | 2.50 | 5.00 | 5.00 |

| BCBSS-08 | 50.00 | 2.50 | 6.00 | 5.00 |

| BCBSS-09 | 50,80 | 2.50 | 6.00 | 5.00 |

| BCBSS-10 | 50,80 | 2.50 | 8.00 | 5.00 |

| BCBSS-11 | 50,80 | 4.00 | 8.00 | 8.00 |

| BCBSS-12 | 60.00 | 2.00 | 5.00 | 4.00 |

| BCBSS-13 | 60.00 | 2.50 | 5.00 | 5.00 |

| BCBSS-14 | 75.00 | 2.50 | 5000 | 5.00 |

| BCBSS-15 | 75.00 | 2.50 | 8.00 | 5.00 |