Flat Wire Belt - Welded and Clinched Edge Types

Flat wire belt, also called honeycomb conveyor belt. It is the combination of flat sheet strips and round wire cross rod. The flat wires are arranged in the form of lattice and jointed with the straight round rods. The material of flat wire belt are commonly high carbon steel, galvanized steel, stainless steel and other materials.

Flat wire belt is a perfect products with both durability and suitable open area. It is temperature resistance, which is popular in the baking conveying applications. The flat surface of honeycomb conveyor belt supplies stable conveying during using.

Edge of flat wire belt

The edge of flat wire belt has two types. They are all solid and durable, you can choose the perfect one you like.

- Clinched edge.

- Welded button edge.

FWB-01 clinched edge of flat wire belt.

FWB-02 welded button edge of flat wire belt.

Specifications of flat wire belt

- Material: high carbon steel, galvanized steel, stainless steel and other materials can be customized.

- Mesh size: 1" × 1", 1/2" × 1", and 1/2" × 1/2".

- Belt width: 0.5m - 3.5m. Special widths can be customized.

| Item | Cross rod diameter (mm) |

Cross rod pitch (mm) |

Nominal pitch (mm) |

Flat strip sizes (H × T) (mm) |

|---|---|---|---|---|

| BFWB-01 | 3 | 13.7 | 14.6 | 10 × 1 |

| BFWB-02 | 4 | 26.2 | 15.55 | 12 × 1.2 |

| BFWB-03 | 3 | 27.4 | 15.7 | 9.5 × 1.25 |

| BFWB-04 | 3 | 27.4 | 24.7 | 9.5 × 1.25 |

| BFWB-05 | 3 | 28.6 | 15 | 9.5 × 1.3 |

| BFWB-06 | 3 | 28.6 | 26.25 | 9.5 × 1.3 |

| BFWB-07 | 4 | 28.4 | 22.5 | 15 × 1.2 |

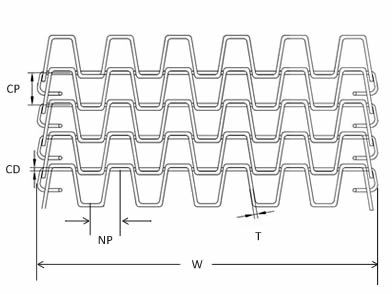

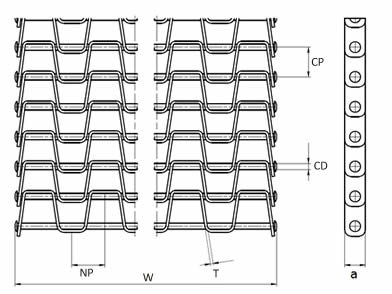

Drawings of flat wire belt

Here are two drawings about the flat wire belt, it can help you know the flat wire belt better. You can refer to that and give specifications as detailed as possible to us to get the accurate quotation.

- W: overall belt width.

- T: thickness of flat strip.

- NP: nominal lateral pitch.

- CP: cross rod pitch.

- CD: cross rod diameter.

Clinched flat wire belt drawing.

Welded button flat wire belt drawing.

Features of flat wire belt

- Flat surface. The flat surface of honeycomb can ensure the stable and high efficient conveying.

- High strength-to-weight ratio. It can improve the energy efficiency during using.

- Large open area. The large open are of flat wire belt make it suitable for the process of drying, washing, baking and cooling.

- Good air permeability and drainage performance.

- Sprockets can be added to the belt. To ensure the smooth and quickly operation, the sprockets can be added to the honeycomb conveyor belt during usage.

- Baffles are available. In the conveying process, to prevent the products from falling down, baffles are added to the flat wire conveyor belt to ensure the products in place.

- High temperature resistance. The high quality materials of flat wire belt are all high temperature resistance, so it is popular in the baking applications.

Sprockets can ensure the smooth and quick conveying of flat wire belt.

Baffles can ensure the products being conveyed in place.

Application of flat wire belt

The flat wire belts, with high temperature resistance, large open area, flat surface is widely used in the following applications.

- Baking.

- Cooling.

- Freezing.

- Washing.

- Drying.

- Clearing.

- Recycling.

- Sorting.

- Packaging.

- Loading.

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@metalconveyorbelts.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.